Revolutionizing the Cold Chain:

Smart Technology Solutions for Cold Storage Efficiency

A New Era for Cold Storage Efficiency

Today’s cold chain is undergoing a digital transformation. As global demand for fresh and frozen goods surges, so does the pressure on cold storage logistics, refrigerated storage services, and temperature-controlled warehouses to perform at peak efficiency. From pharmaceuticals to perishable foods, and sensitive electronics, the need for precise temperature control, accurate tracking, and reliable visibility has become critical.

Heartland is the leader in solutions for cold chain management, giving customers tools to simplify track and trace, reduce spoilage and increase efficiency. No matter the cold chain environment, Heartland has expert solutions designed to help operators meet regulatory requirements, enhance visibility, and maximize productivity.

Common Challenges in Cold Storage

Operating in industrial cold storage environments presents a unique set of challenges that can significantly impact productivity, safety, and compliance. From extreme temperatures that damage equipment to strict regulatory demands and visibility gaps, cold chain operations must overcome multiple obstacles to maintain efficiency and product integrity.

Downtime and Equipment Failure

Extreme cold environments take a serious toll on standard electronic devices. Low temperatures can degrade battery performance, fog up screens, and cause internal components to malfunction. This leads to frequent, unplanned downtime, device failure, and costly operational delays.

Regulatory Compliance

The cold chain is subject to stringent regulatory requirements like the FDA food code, or FSMA. These regulations demand precise record-keeping, traceability, and proof of maximum cold hold temperatures. Companies must ensure that their cold storage solutions can capture and store accurate data in real time to meet regulatory standards and withstand inspections.

Lack of Visibility

Cold storage operations often span large facilities or extended supply chains where real-time visibility is essential but hard to maintain. A lack of visibility can lead to spoilage, stockouts, or overstocking, especially problematic in cold storage for food, where shelf life is limited and quality is critical.

Traceability Challenges

In the event of a product recall, the ability to trace goods from source to shelf is crucial. However, poor labeling, manual logging, or disconnected systems can create gaps in traceability, compromising not only safety and compliance but also brand trust.

Connectivity Gaps

Metal racking, insulated walls, and thick freezer doors often create "dead zones" in temperature-controlled warehouses. These Wi-Fi or Bluetooth connectivity gaps can cause device sync failures, data loss, or delays in communication. Reliable wireless communication is essential to ensure that location data, temperature logs, and task updates are transmitted in real time.

Lifecycle Management

Prolonged use in cold, humid, or icy environments results in faster hardware degradation, more frequent maintenance needs, and higher replacement rates. This increases the Total Cost of Ownership (TCO) and strains IT support teams. Investing in lifecycle support tools like AlwaysOn extends device lifespan and simplifies asset tracking, software updates, and overall device management.

Technology Solutions Designed for Cold Storage

To overcome the operational challenges of cold chain environments, businesses are turning to specialized technology built for sub-zero performance. Unlike standard hardware, these rugged printing and mobility solutions are engineered to withstand freezing temperatures, moisture, and heavy use without compromising functionality.

From mobile computers to industrial printers, each device type plays a critical role in streamlining workflows, maintaining compliance, and enhancing real-time visibility in cold storage logistics.

Industrial Printers

- Built-in heaters prevent label jams and ensure smooth operation.

- Print durable, freezer-grade labels that withstand moisture and temperature changes.

- Integrate with WMS and quality assurance systems for end-to-end labeling automation.

- With all metal parts, our industrial printers are built to endure 24/7 operation in cold conditions.

Cold-Ready Barcode Scanners

- Instant scanning of frosty or damaged labels.

- Flexrange™ capabilities for scanning from an arm’s length to 33’.

- Ergonomic designs to reduce worker fatigue in tough environments.

Vehicle Mounted Tablets (VMUs)

- Mounted directly on equipment like forklifts to minimize handling.

- Operate reliably in extreme cold, with heated screens and rugged casings.

- Glove-friendly touchscreens forklift operators can rely on.

- Smart docking features to enable mounting and removal in seconds.

Keeping the Cold Chain Connected

In any modern warehouse, wireless connectivity is essential… but in temperature-controlled warehouses and refrigerated storage services, it’s mission-critical. Without a reliable network, even the most advanced hardware can’t perform. Wireless downtime can cause disruptions to real-time data capture, live inventory tracking, barcode scanning, and temperature monitoring, bringing productivity to a standstill.

That’s why Heartland is proud to offer AlwaysConnected, a reliable way to unify your wireless network. From insulated walls, metal shelving, and freezer doors that block Wi-Fi signals, we understand the unique challenges cold storage facilities present. AlwaysConnected delivers robust site surveys, wireless design and installation services to keep your teams connected.

AlwaysConnected services include:

- Site surveys to identify interference and dead zones

- Access point placement optimized for cold zones and high-density racking

- Ruggedized wireless infrastructure rated for sub-zero temperatures

- Roaming optimization for mobile workers and vehicle-mounted devices

- Bandwidth planning to support high device volumes and data-heavy operations

Partnering with Heartland’s wireless networking experts ensures your infrastructure is tailored to the demands of cold storage logistics. Interested in learning more?

20 MINUTES CAN CHANGE YOUR BUSINESS

Optimize your Network and Devices

in Cold Storage

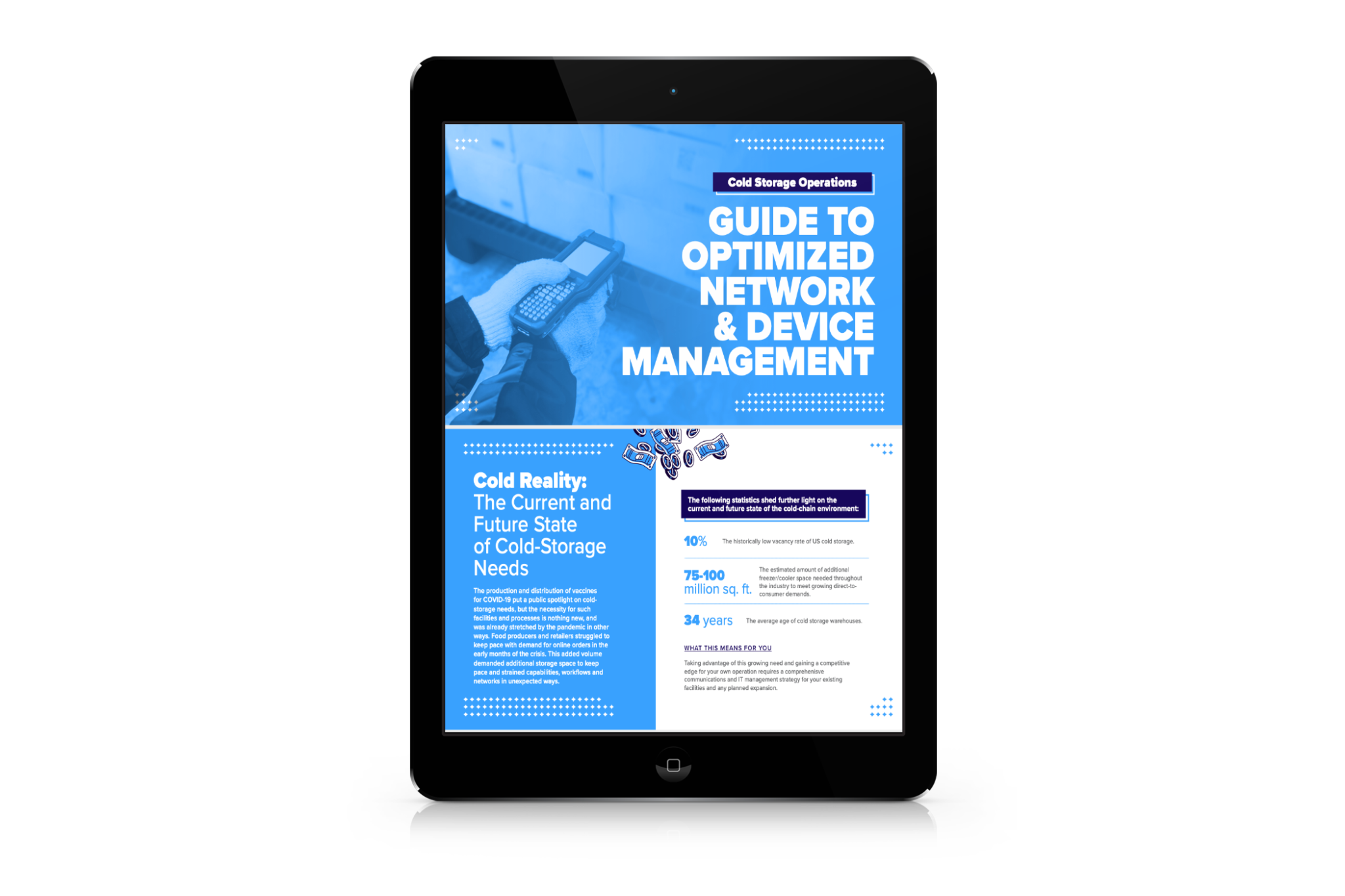

Get our free eBook on how to overcome the big cold management challenges.

Delivering Cold Chain Technologies from Leading Manufacturers

At Heartland, our systems engineers are experienced in recommending the right cold storage solutions for your business’s unique needs. From refrigerated storage services, to temperature controlled warehouses and beyond, we deliver hardware from today’s leading manufacturers that solve for your cold storage needs.

We know that there are an overwhelming number of manufacturers and solutions to choose from. That’s why when you partner with Heartland, you can rest assured that our experts will work to understand your business and operational pain points, and make recommendations with your specific needs in mind.

Proven Partnerships

Heartland is pleased to work with expert hardware and software providers that are leading the charge in voice-guided productivity solutions.

From retail to manufacturing, Honeywell barcode scanners, printers, mobile computers and RFID solutions are purpose-built for the demands of your business. As a pioneer in the barcode scanning market, Honeywell’s experience, combined with new innovations have helped retailers, distribution centers, transportation and logistics and healthcare organizations achieve significant improvements in efficiency, speed and accuracy of their operations.

Zebra anticipates operational challenges so you can scan anything, anywhere, no matter what. Powered by our proprietary DataCapture DNA, everything arrives prepared for duty—ready to deploy, easy to manage, and made to scale. Zebra’s mobile computers, multi-tasking tablets and steadfast printers integrate easily, pair instantly and talk freely to one another to make your workers unstoppable.

TSC Printronix Auto ID is a leading designer and manufacturer of innovative thermal printing solutions. TSC Auto ID offers budget-friendly desktop printers to high-performance industrial solutions including rugged mobile printers. Printronix Auto ID offers premium, enterprise-level applications with a selection of high-end features including RFID encoding and integrated barcode verification.

Click here to see a full list of our hardware and software providers.

The Heartland Difference

Every business is unique, and not all technologies are created equal. That’s why working with an experienced solutions provider is critical to selecting, implementing cold storage mobile technologies that are right for you. The Heartland team draws on decades of supply chain experience that gives your businesses a competitive edge when you need it most. With Heartland, you have access to:

- Unmatched expertise across brands and devices

- Support through every phase of the solution lifecycle, with AlwaysOn suite of managed services

- A wide offering of barcode technologies from today’s industry-leading OEMs

Looking to consolidate vendors for all of your cold storage technology needs? Heartland offers a single point of contact, from device selection, to deployment, ongoing support and more. Our experienced solutions consultants are ready to learn about and understand your operational pain points to recommend best-in-class solutions that make the most sense for your business.

EVERYTHING YOU WANT TO KNOW ABOUT COLD CHAIN

Frequently Asked Questions

What is cold chain?

A cold chain is the temperature-controlled production, storage, and distribution of climate-sensitive goods in supply chain management.

What is a cold chain process?

A cold chain process is a temperature-controlled action or step in the production, storage, and distribution of climate-sensitive goods.

What is a cold chain project?

A cold chain project is an undertaking, carried out individually or collaboratively and possibly involving research or design, to achieve the temperature-controlled production, storage, and distribution of climate-sensitive goods in a supply chain.

What are the components of the cold chain?

The main components of a cold chain are manufacturing, transport and storage, personnel, and all associated equipment, processes, and procedures.

What is cold chain transport?

Cold chain transport is the temperature-controlled movement of climate-sensitive goods from one place to another.

What is cold chain compliance?

What is cold chain management?

Cold chain management is the oversight of climate-sensitive goods as they move through the supply chain.

What is cold chain storage?

Cold chain storage is storing climate-sensitive goods within a specified temperature range.

What is cold chain technology?

Cold chain technology is software and equipment used to control the temperature of climate-sensitive goods during production, storage, and distribution.